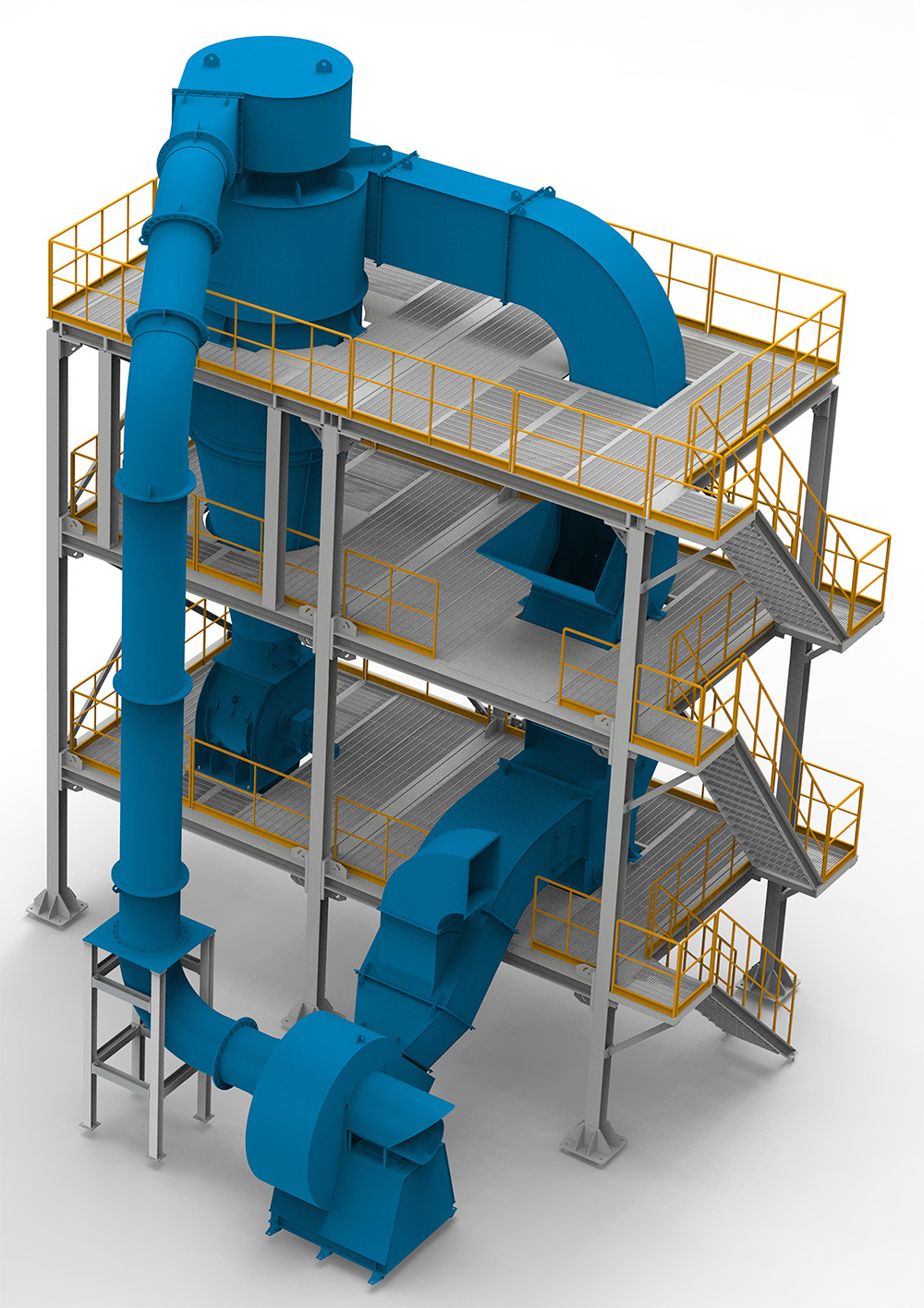

1.Air Separation

The air score system is composed of a blasting cylinder, Z box, pipeline, fan, platform, etc. After the material enters the Z box, it is separated from the special structure of the Z box. , Discharged through the ash valve, the heavy material material fell naturally along Box Z, and entered the next process

| Type | Fan motor(kw) |

static |

Cyclone |

Discharge |

Zbox |

| ASS-50110 | 45 | 2200 | ⌀1500 | 600 | 950*600 |

| ASS-70115 | 1332 | 5000 | ⌀2100 | 1000 | 1367*1166 |

2.Dust removal system

The dust removal system is divided into wet dust collector and dry dust collector. The wet dust collector is composed of self-cleaning water tank, scrubber tower, cyclone, venturi, washing bucket, etc.

3.Trommel

Product description

The trommel screen adopts wear-resistant plate, the frame supports firmly, the top is equipped with cover and dust removal outlet, and the stepless speed change. The material is divided into 0-6mm,6-25mm,25-80mm, >80mm four sizes,

Rotating diameter :1800mm

Effective length:7000mm

Driving power:2x7.5kw

Product advantage

(1)Trommel has solid construction,and enjoy long life time.The driving wheels are of friction-resistant rubber and yield very small vibration and very small noise.

(2)High screening efficiency and large output, the technology is simple, the installation and maintenance is convenient,the operation is convenient.

(3)Small space required, low investment cost, stable and reliable running.

(4)Low power, low energy consumption, with cleaning device equipped inside, the screens holes are not easy to be blocked.

(5)Strong adaptability to all kinds of materials including material with high viscosity or high humidity, dirt materials and mixed materials. Bag shredding device can be added if necessary.

4.Two-shaft shredders

Product description

The two shafts shredder is designed with a double -knife roller symmetrical design structure. The material can naturally fall into the crushing area of the knife set through the inlet warehouse. There is no need to push the feed device to achieve the automatic moving of each cutting knife roller. Group, carrier, box bracket, feeding system, power system. Electrical control system and other composition

Working principle

Metal tear machining uses the comprehensive effect of tearing, squeezing, and cutting the metal to tear, squeeze, cutting. Slim into a small piece of material. Dowry from the lower part of the box. Its working principle is driven by the continuous drive of a large torque motor reducer. The blade set of the blade of the spilling machine is squeezed, teared, and cut into the metal of the Srip Box body , Metal is torn into small pieces of small pieces of specifications

Product advantage

(1)Hexagonal shaft and unique design make it more convenient to disassemble and replac knives,

(2)Automatic microcomputer control with start, stop, reversing and overload automatic reversing control functions;

(3)High-strength steel plate welded to resist high torque, the body is robust and durable, the equipment has lhe characteristics of low torque, high torque and low noise;

(4)With intelligent centralized lubrication system, the oiling time and oiling quantity can be set to avoid the phenomenon of clamping due to lack of oil in the bearings caused by manual negligence;

| Type | unit | DSH-1600 | DSH-1900 |

| Feeding width | mm | 1600 | 1900 |

| Shaft peak torque | Nm | 68000 | 80000 |

| Cutter force at Tip | N | 160000 | 185000 |

| Shaft rotating speed | rpm | 40 | 42 |

| Main motor | KW | 90*2 | 150*2 |

| Material density | t/m3 | <0.8 /UBC,ALU | <0.8 /UBC,ALU |

| Capacity* | t/hour | 8-12 | 18-22 |

Application Cases

Do you have any questions? We’ll get back to you.